Structural Bio-based Polymers, Fibers, and Composites

Slanting towards environmental and economic concerns, I aspire to develop structural green composites for multifunctional applications ranging from automotive, economic packaging, and sports to textile applications. Aiming to replace synthetic polymers or plastics, my research optimizes the properties of natural polymers such as protein, cellulose, and other carbohydrates, etc., and nanomaterials to develop fully bio-based high-performance structures. Also, I seek to develop various bio-based fibers such as cellulose fibers with exceptional properties and added functionalities that can replace glass and carbon fibers.

Figure: Green composite from eggshell

waste

Functional Biomaterials for Food and Energy Sustainability

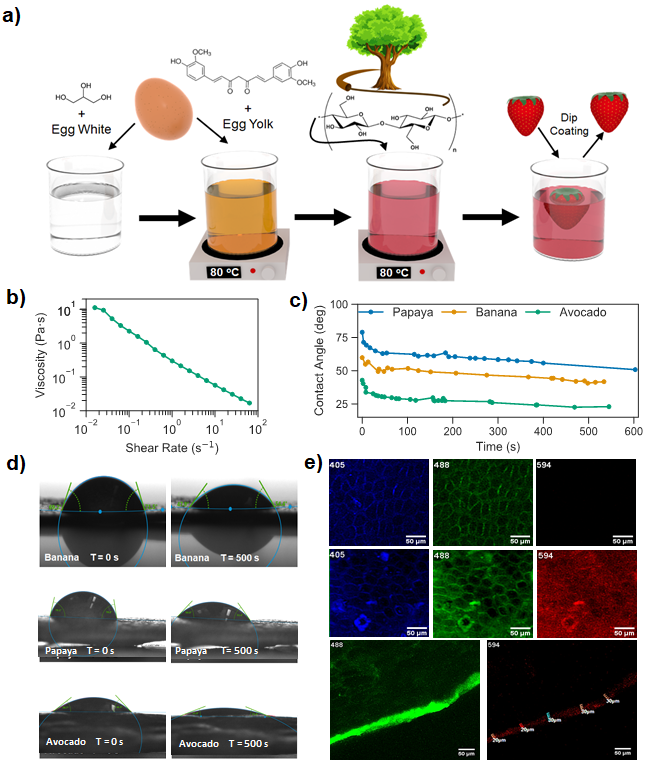

Figure. Bio-nanocomposite coating for perishable fruits

Food security is the most essential requirement for humans; however, providing sufficient, safe, and nutritious foods is becoming a significant challenge to feed a projected global population of 9.7 billion by 2050. As of now, world hunger and chronic undernourishment are exigent global issues, impacting over 800 million people. Around 25% of worldwide freshwater consumption is used to produce foods that are never eaten, and these food wastes generate 8% of the total anthropogenic greenhouse gas (GHG) emissions. In response to this, multi-faceted solutions focusing on food security, safety, and waste reduction are one of my research emphases in the future. I aim to expand the scope of biomaterials and nanomaterials by demonstrating how they can be engineered to interface with foods and plants to boost food security. On the other hand, due to significant environmental challenges posed by the electronics industry, including the depletion of fossil resources, electronic waste (e-waste) generation, and hazardous substance use, I am highly interested in developing functional materials catered to futuristic green electronics. Recently emerged electronics that require flexible polymer-based dielectric and conductive materials rely upon traditional non-degradable synthetic polymers. An effective solution to this bottleneck could be the utilization of biopolymers derived from natural sources such as plants and/or living organisms. I believe the current and forthcoming paradigm in materials engineering is the design of high-performance biopolymer-based functional materials as compelling and green substitutes for the synthetic polymers currently in use.

Structural nanocomposites and laminated composites

Figure: Crack-opening and crack-

sliding displacement fields of

modified thermosets

I aim to understand the processibility of polymers and vitrimers. Thermoplastic composites, even though recyclable, have several manufacturing limitations, e.g., high processing temperature and high viscosity of the polymer above melting temperature that makes impregnation of the reinforcement challenging. I am interested in polymer and vitrimers processing via injection molding, extrusion, resin transfer, compression molding, and additive manufacturing (AM) based advanced manufacturing. I want to study the processibility and properties of polymers and vitrimers and understand the effect of incorporating 1D/2D nanomaterials to develop nanocomposites. Overall, my goal is to understand the fundamental mechanisms by which the additives enhance the structural performance of the polymer composites and to reveal how these mechanisms are affected by the geometry, interface strength, loading fraction, and dispersion. The fundamental knowledge gained will be applied to establish processing-structure-property relationships

that will be used to engineer next-generation composites with shape-memory, self-healing, and damage-sensing capabilities. Also, I plan to infuse sustainability into the composite development technologies by first developing fibers and nanomaterials from waste sources and then utilizing these fibers and nanomaterials to reinforce recyclable polymers and develop composites. I plan to create thermoset and thermoplastic composites with high-volume CNTs fibers to develop novel composite materials with higher toughness and interfacial strength, both of which will prevent the early delamination of composites.